About

5-Axis Water Jet Cutter

As pioneers of waterjet cutting in Queensland, Queensland Gaskets delivers precision and efficiency across projects. We offer decades of experience in high-pressure waterjet cutting and jet cutting services that support diverse industries.

Our operations use cutting edge technology and advanced machinery to achieve precise results. The cutting head on our systems directs ultra-high-pressure water and abrasive media to deliver accurate, repeatable outcomes on complex profiles.

Water jet cutting requires specialised equipment that meets strict tolerances as defined by material and design requirements. Compared with traditional cutting methods, our waterjet solutions offer excellent edge quality without heat-affected zones, reducing the need for secondary finishing.

5-Axis Water Jet Garnet Cutting Applications

Garnet Water Jet Cutting

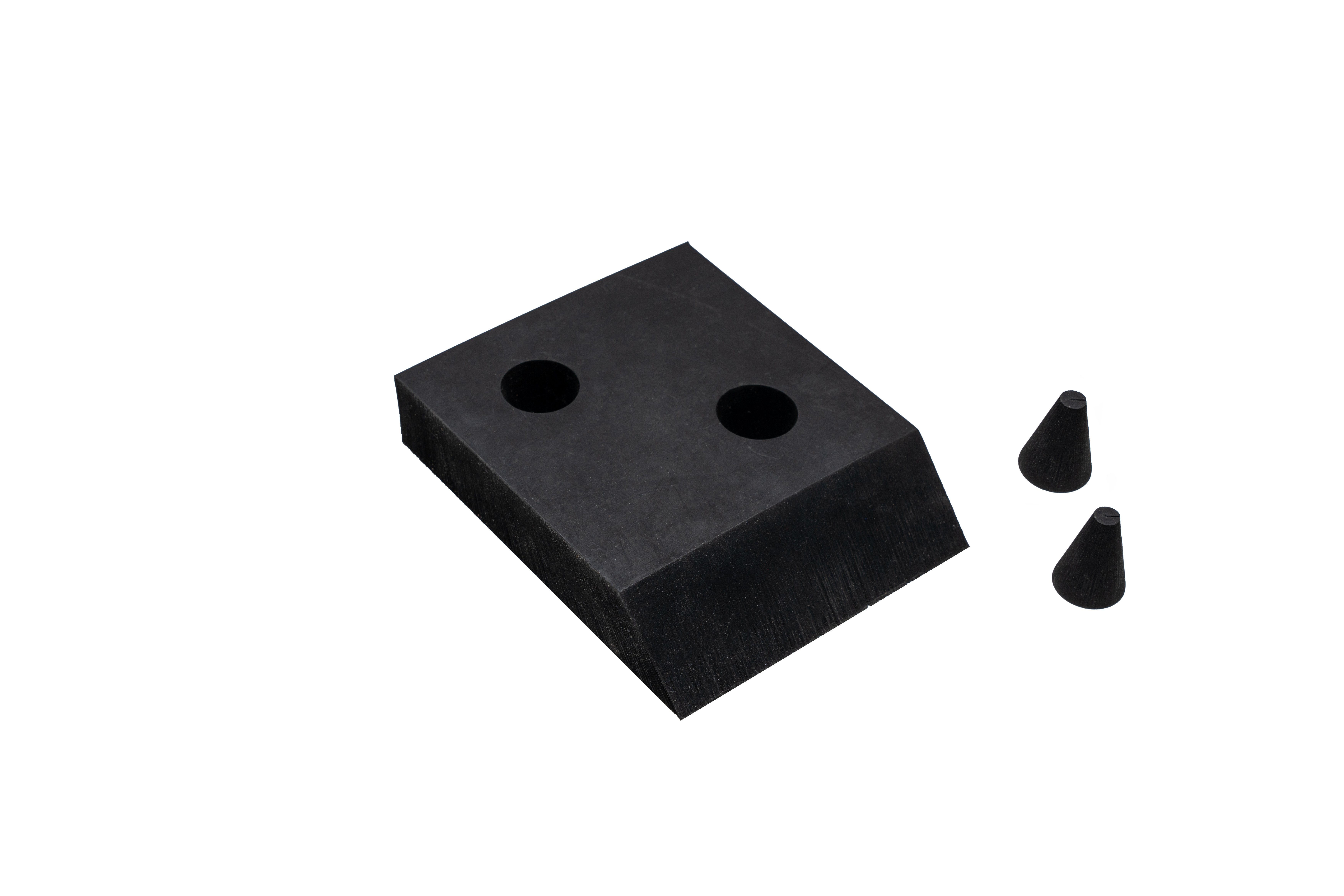

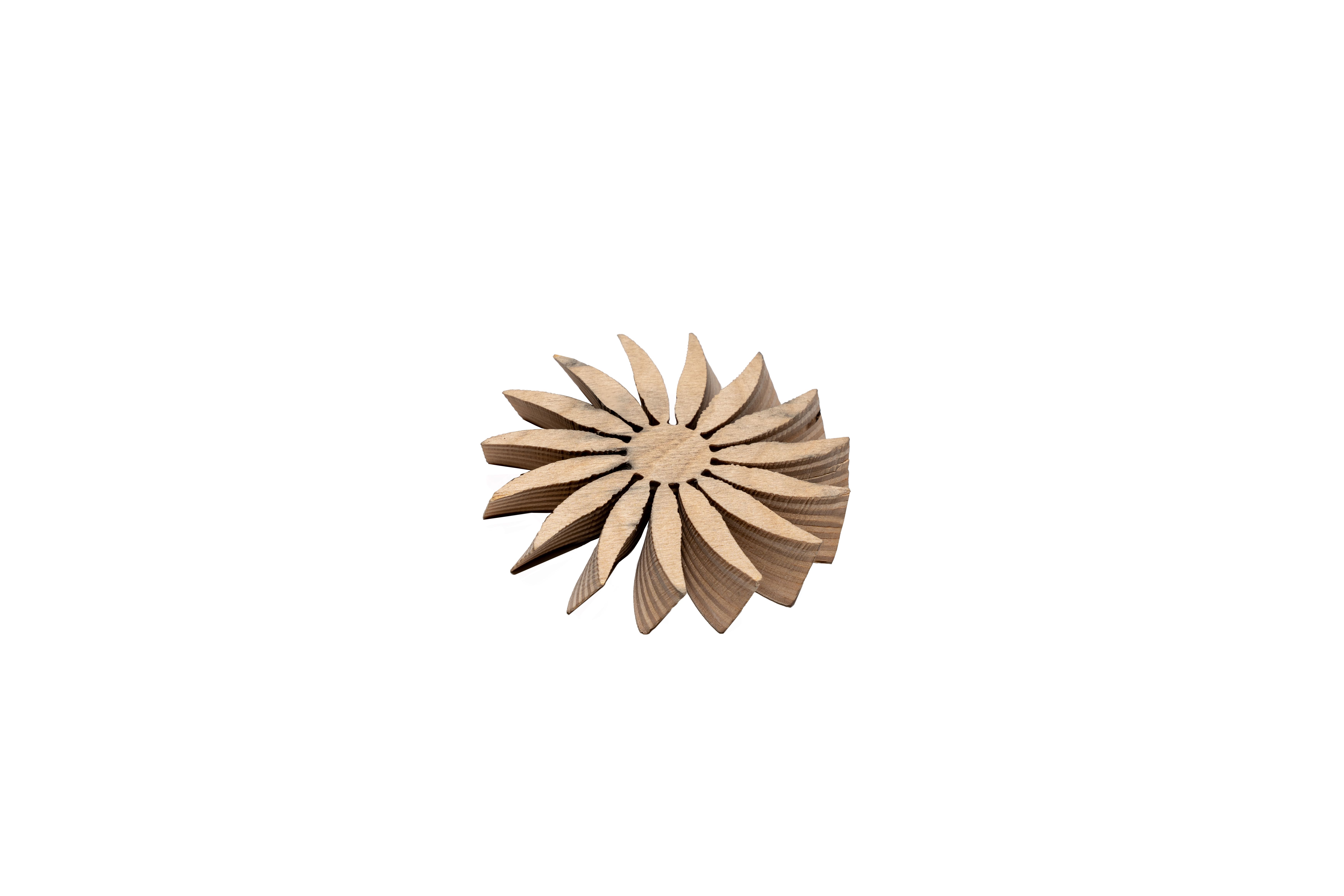

By utilising our 5-axis water jet garnet cutter, less dual processing is required meaning greater cost savings for your project and company. Our garnet waterjet cutter is designed for harder, more difficult materials such as laminated shims, stone, metals, engineering plastics, and Armour Plate. For metals we can cut 2850mm x 1450mm x 110mm.

Specialised Water Jet Cutting & Machine Applications

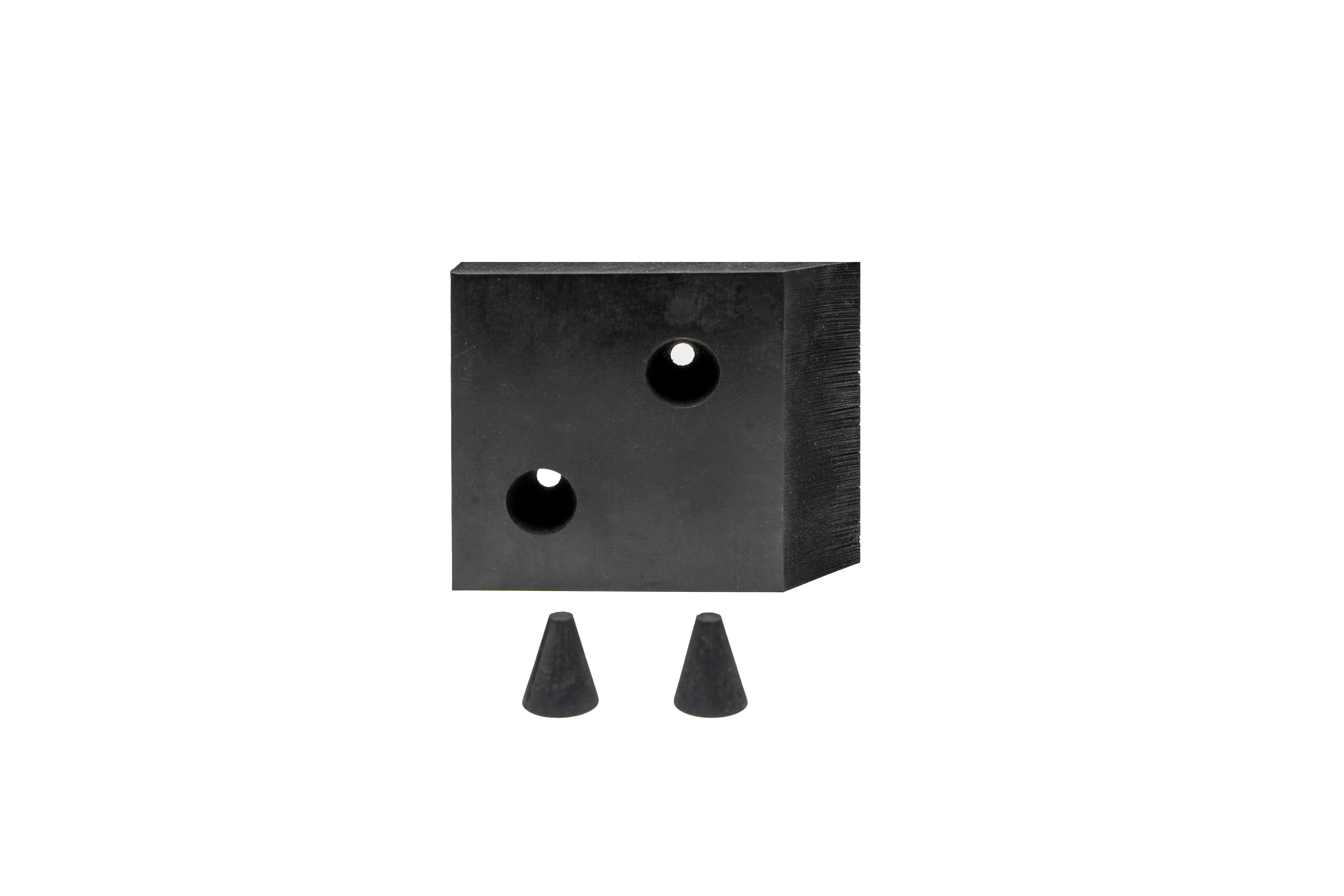

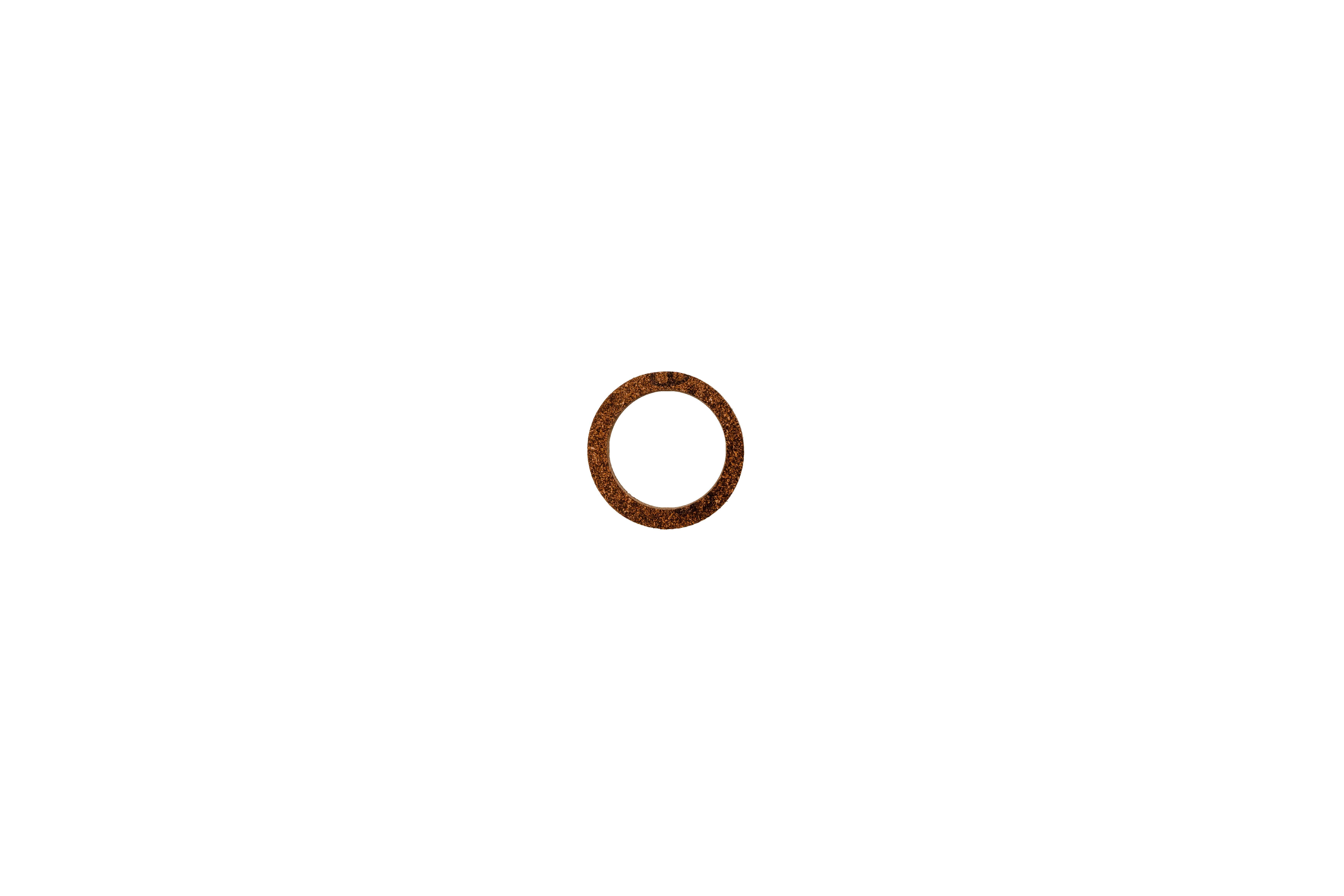

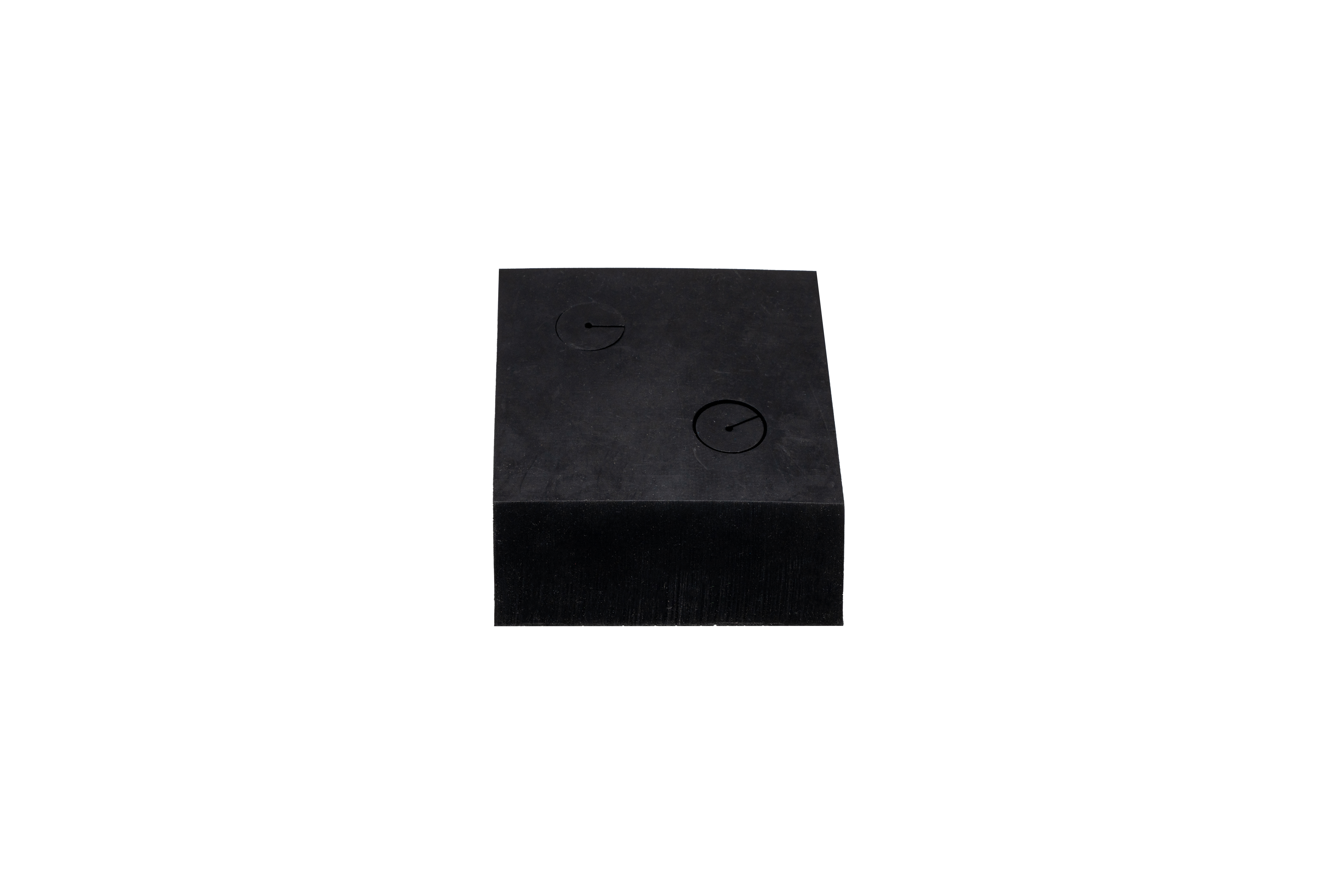

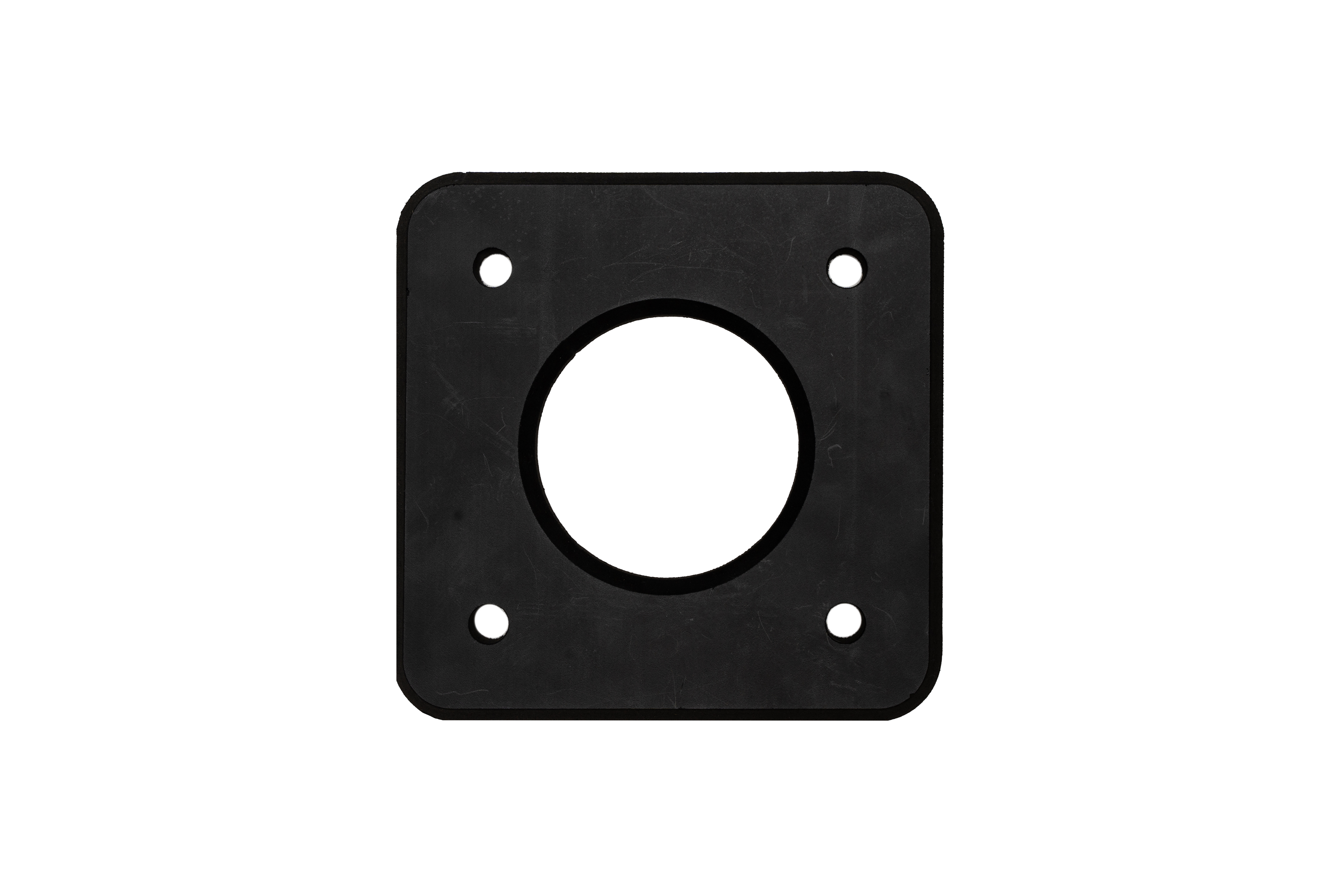

The waterjet cutting process is ideal for multiple applications due to its capability to cut small or large slots and holes in various thicknesses and grades of material. Unlike heat-based methods such as laser or flame cutting, this process reduces machining time and maintains material integrity.

This capability enables intricate designs to be cut with accuracy, supporting projects requiring fine detail and complex contours.

Water Jet Cut Sponge

Water Jet Cut Cork

Water Jet Cut Rubber

Water Jet Cut Foam

Water Jet Cut Stone

Water Jet Cut Plastic

Water Jet Cut Metal

Water Jet Cut Fibre

How we use our 5-axis water jet cutting machine for projects

The 5-axis water jet cutting capabilities of Queensland Gaskets are beneficial for a number of our customers, in various industries. Due to our extensive experience, we are able to save time and keep production timelines to a minimum for each project.

Some examples of the abilities of our 5-axis water jet machines include:

- High-precision 3D parts cut from the toughest metals, fibers, and alloys.

- Prototyping with complex shapes and models.

- Automobile gears and engine components, small and large.

Our team applies industry knowledge and cutting edge technology to tailor the cutting head setup and maintain excellent edge quality, even on complex profiles.

Frequently Asked Questions

5-axis water jet cutting uses high-pressure water mixed with abrasive to cut materials. The machine moves in five directions: X, Y, Z, A (tilt), and C (rotation). This allows it to cut straight edges, bevels, and complex shapes in a single pass. It does not use heat, so the cut edges stay clean and free from heat damage.

It delivers precise cuts without heat-affected zones. This keeps the material’s strength and finish intact. The process reduces the need for extra machining, saving time and cost. It can cut complex shapes in one setup, making it ideal for both prototypes and production runs.

Yes. We distribute both interstate and globally.

Our industrial gaskets are used by sugar mills, hospitals, mining, shipbuilding, alumina plants, railways, truck assembly plants, sewerage plants, pipeline constructions, water supply, foundries, breweries, food processing plants, fire prevention, refrigeration, sand mining and dredging, electricity generation and many other applications.

We offer a wide selection of materials, cutting processes and use of technology, as well as AutoCAD Drawing Conversion and Rapid Prototyping (utilising 3D printing and CNC cutting methods.)

Our machinery includes Press Cutting, Tooling/Dies, Existing Tooling, Samco Conveyor Press, Slitting, high-pressure abrasive Water Jet Cut, CNC Router, Gluing Parts, and 3D Printing.

We offer access to an extensive global supply chain. Our material suppliers include for example Bluemax, Donit Tesnit, Specialty Silicone Products and many other local and international partners.

Yes. We can test new materials. They work with clients on single parts or large batches.

The service achieves tolerances of ±0.2 mm. It can cut materials up to 150 mm thick. For metal sheets, the maximum size is 2850 mm long, 1450 mm wide, and 110 mm thick. This makes it suitable for both small precision parts and large industrial components.

Demonstrated 5 Axis Water Jet Machine Cutting