About

CNC Knife Cutting Services

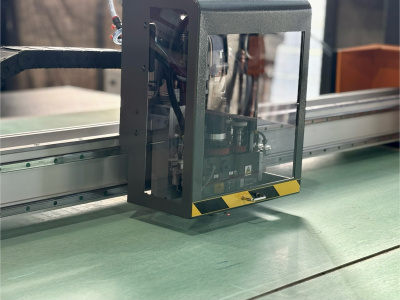

Atom Knife Cutter is a high-performance CNC knife cutting machine designed for cutting semi-rigid and rigid materials up to 20 mm thick. It features a robust, precise, and state-of-the-art mechanics and electronics that ensure maximum reliability and cutting capability. This machine is capable of handling sheet sizes up to 3050mm x 1550mm.

The Atom Knife Cutter presents a more economical solution compared to waterjet cutting, closely aligning with traditional press cutting methods to reduce both tool production and storage costs. This cost-efficiency benefits our customers by providing more affordable cutting services without compromising on the quality of the cuts.

Materials We Can Cut

The Atom Knife Cutter is designed to handle a broad range of materials. Compatible materials for the Atom Knife Cutter include:

- Gasket Materials: Specialised for cutting various types of gaskets with precision.

- Foam and Rubber: Ideal for cutting soft materials without deforming or overheating them.

- Leather and Textiles: Capable of cutting intricate patterns and designs in fashion and upholstery industries.

- Plastics and Composites (PVC & Vinyl): Suitable for lightweight yet sturdy materials used in various manufacturing processes.

- Cork and Fibers: Handles organic and synthetic fibers effectively.

This versatile capability allows us to undertake projects that require cutting a variety of materials with high precision and minimal waste.

CNC Knife Cut Fibre

CNC Knife Cut Plastic

CNC Knife Cut Rubber

CNC Knife Cut Foam

CNC Knife Cut Cork

CNC Knife Cut Textile

CNC Knife Cut Vinyl

CNC Knife Cut PVC

Advantages of the Atom Knife Cutter

Choosing the Atom Knife Cutter brings several significant advantages to our operations:

- Precision and Versatility: The machine ensures high precision with a tolerance of +/-0.2mm, ideal for detailed and intricate cuts across various materials.

- Increased Cutting Dimensions: Capable of handling sheet sizes up to 3050mm x 1550mm, it accommodates larger materials, which enhances our production flexibility.

- Cost-Effectiveness: It minimises the necessity for new tooling and optimises material usage, leading to reduced operational costs.

- Enhanced Productivity: By redistributing work from our busiest machines, the Atom Knife Cutter improves our overall efficiency and speeds up order processing times.

- Advanced Capabilities: With features like precision hole punching, the machine not only cuts but also adds detailed functionalities to components, enhancing the quality of the final product.

Our existing Multicam knife cutter continues to complement our new knife cutter, allowing us to process a broader array of materials more efficiently and swiftly. This integration ensures that we can deliver projects to our customers more quickly.

CNC Knife Cutting In Action