Gasket failure happens when a gasket can no longer maintain an effective seal. This failure can lead to leaks, pressure loss, and equipment downtime. Understanding the causes of gasket failure helps maintenance teams prevent damage, control costs, and keep machinery operating safely. This overview gives a clear and practical breakdown of the most common issues that lead to gasket failure.

What Is Gasket Failure?

Gasket failure is the point where a gasket stops performing as intended under normal operating conditions. A gasket should seal two surfaces under pressure, temperature, and load. Failure occurs when the gasket loses its ability to maintain that seal due to damage, wear, or incorrect operating conditions. This breakdown affects how equipment holds pressure, manages heat, and controls fluids. A clear understanding of this failure helps teams assess risk and plan maintenance.

Signs of Gasket Failure

Teams can detect gasket failure early by watching for clear operational changes. Common signs include:

- Visible leaks around the joint or flange.

- Drops in system pressure during normal operation.

- Unusual temperature changes near the sealing point.

- Distorted or damaged gasket material during inspection.

- Increased vibration or noise from connected equipment.

- Bolts that need frequent re-tightening, which signals loss of compression.

Common Causes of Gasket Failure

Many factors can weaken a gasket or limit its ability to seal. The most frequent causes are below.

Incorrect Material Selection

A gasket fails when the material cannot handle the system’s temperature, pressure, or media. Materials can break down, harden, swell, or lose strength when they are not suited to the operating environment. Correct material selection is essential for a stable seal.

Poor Installation

Incorrect installation affects how the gasket seats between surfaces. Common issues include misalignment, uneven bolt load, surface contamination, or damage to the flange. These conditions reduce compression and create gaps that lead to leaks.

Excessive Temperature or Pressure

High or fluctuating temperature and pressure place consistent stress on gasket materials. Thermal cycling, pressure spikes, or exposure beyond the rated limit cause deformation and early failure.

Wear and Ageing

All gasket materials change over time. Repeated compression, heat cycles, and load cause hardening, softening, or permanent deformation. This movement reduces sealing ability and increases the chance of leaks.

Chemical Attack

Contact with incompatible chemicals weakens gasket materials. Swelling, cracking, or loss of elasticity are common results of chemical attack. This breakdown reduces the gasket’s ability to hold a seal.

Flange Problems

A gasket cannot seal effectively if the flanges are damaged or uneven. Warped surfaces, scratches, or incorrect flange load create inconsistencies that the gasket cannot compensate for.

Vibration or Mechanical Stress

Constant vibration or mechanical movement shifts the gasket position over time. Misalignment, equipment movement, or poor system support increases stress on the joint and leads to seal failure.

How to Prevent Gasket Failure

Maintenance teams can prevent gasket failure by controlling the factors that affect sealing performance. The most effective steps include:

- Select the correct gasket material for the temperature, pressure, and media in the system.

- Check flange surfaces for damage, corrosion, or uneven areas before installation.

- Apply the correct bolt load by following recommended torque values and tightening sequences.

- Keep surfaces clean to ensure proper contact and even compression.

- Monitor operating conditions to confirm that the gasket is working within its limits.

- Schedule regular inspections to identify wear, deformation, or changes in performance.

These steps support long-term gasket reliability and reduce unplanned downtime.

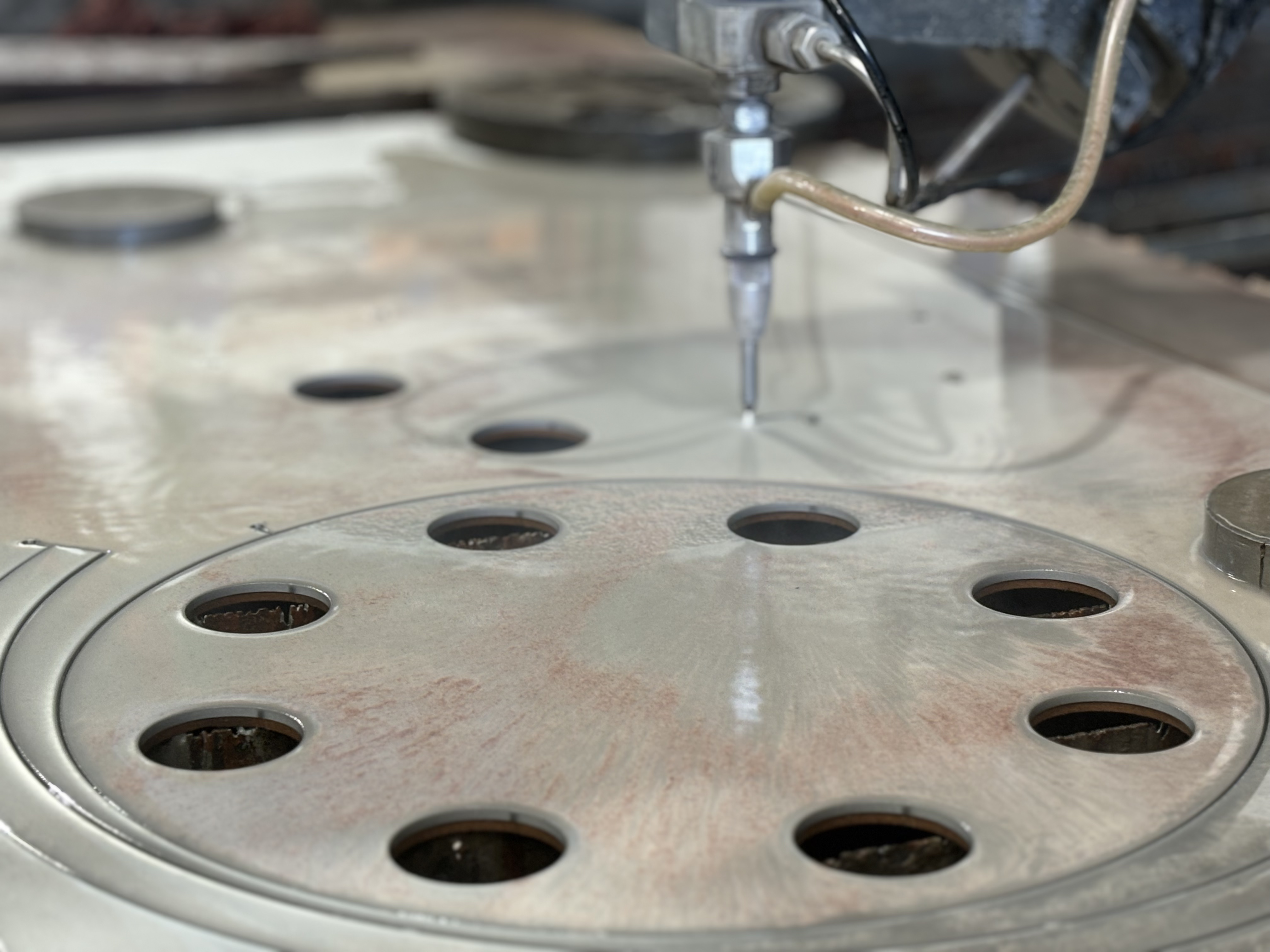

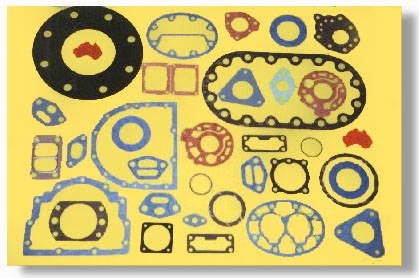

Why High-Quality Manufacturing Matters

High-quality manufacturing reduces the risk of gasket failure by ensuring accurate dimensions, clean cuts, and consistent material performance. Precision in production helps each gasket seat correctly, maintain compression, and withstand operating conditions.

Queensland Gaskets supports this with more than 70 years of industry experience. The team works under an ISO9001:2015 quality system and uses advanced cutting technologies to produce reliable gaskets for a wide range of applications. Local manufacturing also helps businesses access fast supply, accurate replacements, and consistent quality across repeat orders.

When to Contact a Gasket Specialist

A gasket specialist can help when standard checks or routine maintenance cannot resolve an issue. Contact a specialist if:

- Your equipment experiences repeated gasket failures.

- You are unsure which material suits your operating conditions.

- You are setting up new equipment and need accurate specifications.

- Your system runs under high pressure, high temperature, or harsh chemical exposure.

- You need custom gasket designs or precise manufacturing support.

Early support helps prevent long-term damage and ensures the gasket performs as expected.

Contact Queensland Gaskets

Queensland Gaskets supplies high-quality gaskets for a wide range of operating conditions. Our team can help you select suitable materials and produce accurate parts for your equipment. Contact us to discuss your requirements or request a quote.

FAQs

What causes gasket failure?

Gasket failure occurs when the gasket can no longer hold a seal under normal operating conditions. Common causes include incorrect material selection, poor installation, flange damage, chemical exposure, and excessive temperature or pressure.

What are the signs of gasket failure?

Typical signs include leaks, pressure loss, temperature changes, visible wear, distortion, unusual noise, or equipment vibration. These signs show that the gasket is not sealing correctly.

How long should a gasket last?

A gasket’s lifespan depends on material type, operating conditions, and maintenance practices. High heat, pressure changes, chemical exposure, and vibration can shorten the lifespan. Regular inspections help identify wear before failure occurs.

Can I prevent gasket failure?

Yes. You can prevent gasket failure by choosing suitable materials, preparing clean flange surfaces, applying the correct bolt load, and monitoring system conditions. Routine checks reduce the chance of unexpected issues.

When should I replace a gasket?

Replace a gasket when you see leaks, deformation, hardening, surface damage, or any loss of sealing performance. Replacement is also recommended during scheduled maintenance or after equipment disassembly to ensure a reliable seal.